Manufacturer of All Terrain Forklift Lull - REACH FORK TRUCKS FOR TRANSPORTATION – Wilson

Manufacturer of All Terrain Forklift Lull - REACH FORK TRUCKS FOR TRANSPORTATION – Wilson Detail:

Product Parameter

| MODEL XWS-1450 | ITEMS | UNIT | PARAMETERS |

| Performance parameters | Rated load weight (Min. distance from front wheels) | Kg | 5000 |

| Distance from fork center to front wheels | mm | 2200 | |

| Max. lifting weight | Kg | 7500 | |

| Distance from lifting bolt to front wheels | mm | 1000 | |

| Max. liftinging height | mm | 13775 | |

| Max. front extension | mm | 11000 | |

| Max. running speed | Km/h | 30 | |

| Max. climbing ability | ° | 25 | |

| Machine weight | Kg | 15000 | |

| Working device | Telescopic booms | Sections | 4 |

| Stretch out time | s | 12 | |

| Shrinking time | s | 14.5 | |

| Max. lifting angle | ° | 65 | |

| Overall size | Length (Without forks) | mm | 6900 |

| Width | mm | 2300 | |

| Height | mm | 2350 | |

| Distance between shafts | mm | 3500 | |

| Wheels tread | mm | 1800 | |

| Min. ground clearance | mm | 375 | |

| Min.turning radius (Two wheels driving) | mm | 4850 | |

| Min.turning radius (Four wheels driving) | mm | 4450 | |

| Standard fork size | mm | 1200*150*50 | |

| Standard configuration | Engine model | - | LR6A3LU |

| Rated power | Kw | 117.6/2400 | |

| Driving | - | Front wheels | |

| Turing | - | Rear wheels | |

| Tire types (Front/Rear ) | - | 11.00-20 (4/2) |

Product Details

Telehandlers are able to lift heavy loads up to the units lift capacity and height specifications including palletised and non-palletised good when fitted with the correct attachment.

Whilst forklifts are one dimensional in their movement abilities, telehandlers are able to move diagonally allowing them to pick-up and transport loads that a standard forklift would be unable to lift.

With their increased maneuverability telehandlers are able to easily access odd angles and tight spaces with their extendable boom, making them the ideal materials handling solution for confined spaces.

Stabilisers that can be deployed from the unit, provide extra stability and safety when lifting heavy loads.

Telehandlers four wheel drive features allow units to operate both on and off road.

Units are fitted with large robust tyres that are able to support the lifting and transport of heavy loads whilst also providing easy travel across the rough and uneven terrain often encountered on building sites, on farms or agricultural grounds and even mining sites.

Units can also be road registered which allows them to operate on marked bitumen roads so they can safely and easily transport loads to sites when off-loading from delivery trucks or between job sites.

A MULTI-FUNCTION TELESCOPIC LOADER ability to hydraulically lift and maneuver large and heavy loads around sites reduces the need for employees to undertake extensive manual lifting tasks.

This can greatly reduce the chances of them injuring themselves through unsafe or repetitive manual lifting.

To ensure maximum safety on-site telehandlers must only be operated by fully trained and qualified operators.

Operators must have undertaken correct training and hold the correct license to operate the unit safely and be able to respond quickly and safely as possible in the event of an emergency.

It is also important to ensure the telehandler is not pushed beyond the manufacturer’s specified lifting capacity and heights, otherwise this greatly raises the risk of injury, product or equipment damage or even a workplace fatality.

For more telehandler uses and maintenance works, please contact us for the details.

Several steps before you use the telehandlers.

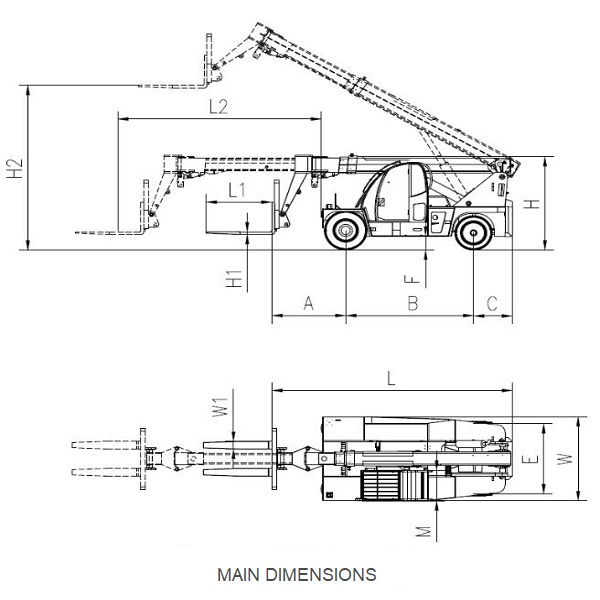

Step1. According to your task, ground grade, wind speed, attachments, choose a suitable machine model. See the parameters, loading diagrams and the overall size of the machine. The overload is prohibited.

Step 2. Install the attachment onto the end of the boom, make sure all the nuts are screwed tightly and the oil pipes well connecting without leaking.

Step 3.Check all the functions to make sure all of them can move smoothly without abnormal sounds.

Step 4.The other requirement please fellow the introductions.

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Manufacturer of All Terrain Forklift Lull - REACH FORK TRUCKS FOR TRANSPORTATION – Wilson, The product will supply to all over the world, such as: Seychelles, Kazakhstan, Greenland, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!